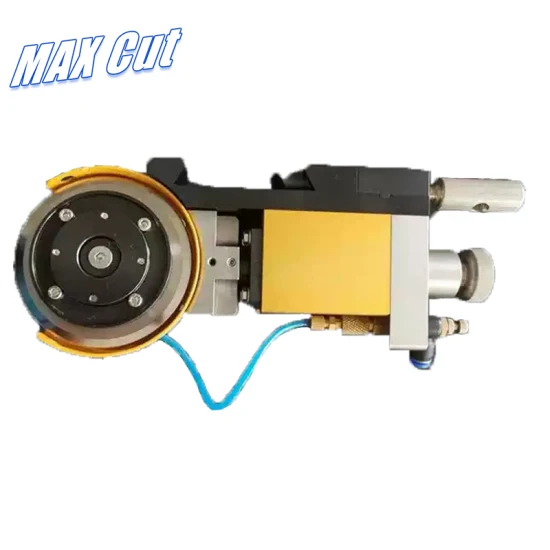

Paper Fabric Non-Woven Textile Machine Pneumatic Slitting Blade Holder

Basic Info

| Model NO. | 150 Blade Holder |

| Customized | Non-Customized |

| Condition | New |

| After-sales Service | 24 Hours Online Service |

| Max Knife Stroke | 30mm |

| Side Closed Stroke | 2.5mm |

| Working Pressure | 4~6kgf/M2 |

| Max. Slitting Speed | 1000m/Min |

| Min.Slitting Width | 50mm |

| Max. Paper Cutting Capacity | 800G/M2 |

| Max. Films Cutting Capacity | 1.5mm |

| Transport Package | Carton |

| Specification | 395*150*50 |

| Trademark | Max Cut |

| Origin | Guangdong, China |

| Production Capacity | 10000 Sets Per Month |

Product Description

Pneumatic slitting knife set , with a variety of special functions, can be embossed, grooved, can be slitting, can also be matched with the production line for material thickness detection. It is easy to install, and is driven by air, with strong structure and high safety.With the improvement of the accuracy requirements of the market for slitting products, the air pressure slitting machine will gradually replace the traditional slitting machine, and its advantages are high slitting accuracy and fast slitting speed.The pneumatic tool holder has high tool loading stability, is convenient and fast, and is also convenient to adjust the slitting size.This round blade, mainly used for non-woven fabrics, paper, film, gold leaf, silver foil, copper foil, aluminum foil, tape and other items of slitter, requires the blade cutting resistance is small, good wear resistance, out of the requirements for commodity accuracy The blade must reach micron-level accuracy when it has it.Our company selects 9CrSi, Cr12MoV (SKD-11), W6Mo5Cr4V2 (high speed steel) steel as raw materials, the use of processing equipment and heat treatment equipment, products are used in textile slitting, non-woven slitting, slitting protective film, tape slitting, film slitting, medical material slitting, paper slitting, chemical fiber slitting, bundled cloth slitting, aluminum foil slitting, paper slitting and other material slitting.

Product Parameters

| Model | 150 |

| Max Knife Stroke | 30mm |

| Side Closed Stroke | 2.5mm |

| Working Pressure | 4~6kgf/m2 |

| Max. Slitting Speed | 1000m/min |

| Min.Slitting Width | 50mm |

| Size of Adaptor | PT1/8'' |

| Max. Paper Cutting Capacity | 800g/m2 |

| Max. Films Cutting Capacity | 1.5mm |

LLY PACK (Foshan) is one of the leading manufacturers for corrugating roller and all types of industrial knives and cutting blades. Our brand"Max Cut" is committed to supply the durable and accurate cutting products to our customer without the troubles.Our factory is located in Foshan City, Guangdong Province, South China. A state-of-the art factory with over 30 sets of high precision CNC machine and the most advanced heat-treatment equipment. Over 20 years of technical experience, we have been continuously striving for top quality cutting knives. We strictly following our standard quality control. Max Cut products are widely applied in various industries, such as: Corrugated Cardboard & Carton Packaging Industry, Paper Mill, Tissue& Towel converting, Plastic& Flexible Packaging Industry, Food Packaging, Tobacco Cutting, Fabric& Textile & Leather Cutting, Film& Foil Cutting, Tube Cutting, Metalworking, Wood processing, Shredder/Crusher Blade and more.Max Cut is always ready to support you the industrial cutting knives with expected quality at the best price and reliable turnaround time.Please join us for"Win-win cooperation".

FAQQ1: Are you trading company or manufacturer?A1: Our factory is a professional manufacturer of industrial blades for more than 20years.Our blades are mainly used in: packaging, paper, rubber, optoelectronics, electronics, light industry, printing, metallurgy, and other machines.Q2: What is your blade hardness?A2: Different material has different hardness, from 48HRC to 68HRC, we can supply all of these. You can describe the use, we'll provide suitable suggestion for you.Q3. Where were cutting blades exported before?A3: Our industrial blade have been exporting to over 40 countries, including: Vietnam, Thailand, Myanmar, Philippine, Malaysia, Indonesia, India, Egypt, Emirate, Bahrain, Saudi Arabic, Israel, Russia, Lithuania, Mexico, Brazil, Argentina, Venezuela, Honduras, Korea and etc.